Checking Out the Art of Cheese Manufacturing: Methods, Processes, and Technologies in the Milk Sector

The exploration of cheese manufacturing includes a varied array of methods and processes that mirror both historic practices and modern innovations within the dairy products industry. By analyzing the elaborate art of fermentation, aging, and modern manufacturing methods, one gains insight right into exactly how craftsmens and large-scale manufacturers alike adjust to developing customer choices and sustainability obstacles. As we take into consideration the implications of these developments, it ends up being important to question how they will shape the future landscape of cheese and its duty in our diets and cooking methods.

History of Cheese Making

Tracing its origins to old civilizations, the background of cheese making reveals a rich tapestry of social and technical evolution. Evidence recommends that cheese production dates back over 7,000 years, with historical searchings for from areas such as Mesopotamia and the Indus Valley showcasing very early dairy products methods. These cultures made use of milk from tamed animals, and through all-natural processes of fermentation and curdling, they created basic kinds of cheese.

As human beings progressed, the art of cheese making ended up being a lot more improved. The old Egyptians and Greeks recorded their techniques, which included a range of milk resources and diverse techniques for aging and flavor cheese. The Romans better sophisticated cheese production, exporting their knowledge across Europe, which resulted in regional adaptations and one-of-a-kind selections.

The Center Ages witnessed the establishment of abbeys as facilities of cheese manufacturing, where monks developed distinct recipes that reflected regional tastes and readily available resources. Throughout the centuries, cheese making has developed, influenced by aspects such as geography, environment, and social techniques. This rich background not just shows the ingenuity of early societies however additionally lays the structure for the diverse cheese varieties enjoyed today around the world.

Traditional Cheese Manufacturing Techniques

Conventional cheese production strategies include a range of time-honored approaches that have been passed down through generations. These techniques, frequently region-specific, mirror the special cultural heritage related to cheese-making. The process usually begins with sourcing top quality milk, which can vary in kind depending on the desired cheese.

Coagulation is accomplished via the enhancement of rennet and often an acid, bring about the development of curds. The curds are after that cut and gently stirred, allowing whey to divide. This initial coagulation phase is critical, as it influences the appearance and wetness content of the end product.

Fermentation and Aging Procedures

Fermentation and aging procedures are important to the advancement of cheese, happening after the initial curdling and pushing stages. During fermentation, details bacterial societies are introduced to the curds, facilitating the conversion of lactose right into lactic acid. This acidity not only helps in curd conservation yet likewise adds to the taste profile and structure of the end product.

As celebrity ages, biochemical responses remain to take place, affecting its taste, fragrance, and appearance. Enzymes and germs damage down healthy proteins and fats, leading to the growth of complicated tastes. The aging environment, consisting of temperature level and humidity, plays an important function in this growth process. Different cheeses need varying aging periods, which can vary from a few weeks to numerous years, bring about distinctive features.

Furthermore, the presence of mold and mildews or yeasts on the cheese surface area can further boost taste complexity. For circumstances, blue cheeses depend on details mold and mildew societies to develop their signature preference accounts. In general, both fermentation and aging are important in defining the originality of cheeses, enabling craftsmens to develop a diverse variety of items that deal with a large array of tastes buds.

Modern Developments in Dairy Production

Innovations in milk manufacturing have actually transformed the cheese-making process, enhancing effectiveness and product high quality. Technological innovations, such as automated milking systems and precision fermentation techniques, have structured operations and boosted consistency in raw milk top quality. These systems decrease labor expenses and improve animal welfare by enabling more comfy and efficient bleeding read methods.

Furthermore, the unification of data analytics and IoT (Net of Points) devices has made it possible for dairy products producers to keep track of numerous specifications, such as temperature and moisture, in real-time. cheese makers melbourne. This ability makes sure ideal conditions throughout the cheese-making procedure, bring about a better end product

In addition, developments in pasteurization methods, including high-temperature short-time (HTST) pasteurization, have not just boosted food safety and security but additionally preserved the fragile flavors and nutrients integral in milk.

Sustainable practices are additionally gaining grip, with improvements in waste monitoring and renewable resource application. Numerous producers are currently taking advantage of biogas from dairy waste, promoting environmental stewardship while all at once lowering operational costs.

These modern-day advancements jointly add to a more reliable, lasting, and high-quality cheese manufacturing process, setting brand-new requirements in the dairy market.

Future Patterns in Cheese Market

As the cheese market remains to progress, emerging trends are reshaping production, intake, and advertising strategies. One substantial trend is the growing demand for artisanal and specialized cheeses, driven by consumers looking for unique flavors and premium ingredients. This shift is urging producers to embrace traditional techniques while including modern innovation for improved high quality control.

Sustainability stays at the center of consumer choices, triggering manufacturers to check out environmentally friendly methods, such as lowering water usage, optimizing power intake, and making use of biodegradable packaging materials. In addition, innovations in plant-based cheese alternatives are expanding market chances, dealing with the boosting variety of vegan and lactose-intolerant consumers.

In addition, digital advertising and marketing and shopping are visit this website transforming how cheese is marketed and offered, enabling producers to link straight with customers and customize their offerings to details demographics. Registration solutions and Read Full Article on the internet platforms are ending up being prominent channels for cheese circulation, improving ease of access and benefit.

Finally, health-conscious patterns are affecting cheese formulations, with manufacturers developing lower-fat, lower-sodium, and nutrient-enriched alternatives to meet customer needs. As these fads remain to unravel, celebrity market is most likely to witness a dynamic makeover that straightens with contemporary consumer worths and preferences.

Verdict

The expedition of cheese production reveals a complex interaction of time-honored techniques and modern developments. As the dairy market welcomes health-conscious trends and green methods, the future of cheese manufacturing assures continued development and advancement, ensuring its enduring importance in cooking society.

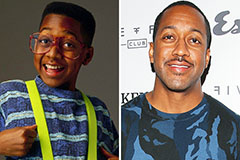

Jaleel White Then & Now!

Jaleel White Then & Now! Luke Perry Then & Now!

Luke Perry Then & Now! Tina Majorino Then & Now!

Tina Majorino Then & Now! Nadia Bjorlin Then & Now!

Nadia Bjorlin Then & Now! Nicholle Tom Then & Now!

Nicholle Tom Then & Now!